Wear, in material science, simply means erosion or the displacement of a material from its original form. It can happen on its own or be caused by contact with another surface. Abrasive wear takes place when a rough, hard surface glides across a surface that is relatively softer.

Abrasive wear occurs when a hard surface or hard particles pass over a soft surface, causing loss of material . However, the abrasive grooves can be found on the wear tracks of the sliding friction between similar metals . It means that abrasive particles may be formed during the wear process due to work hardening, phase transformations and third body formation at the interface.

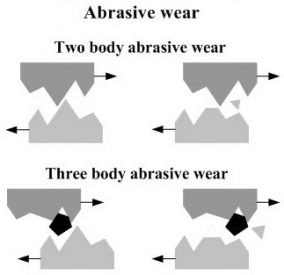

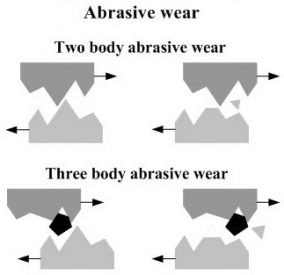

Abrasive wear can be divided into two groups: two-body and three-body abrasive wear. In the three-body abrasion, the particles formed during the operation or coming from outside the system cause the abrasive wear, whereas in two body, one of the materials plays the role of the abrasive.

Abrasive wear has three different forms: microcuting, wedge forming and ploughing . During operation of a system, transition from one mode to another may happen and modes can act simultaneously. In the ploughing mode, a shallow groove is formed and repeated loading is necessary to form a wear particle. In the wedge forming, the wedge type of wear debris is formed. In the microcutting mode, long, curled ribbon-like particles are generated. The shape of the abrasive particle, the hardness, the load and the shear strength at the contact interface determine the state of the abrasive wear. The abrasive wear coefficients of metals are in the range of depending on the conditions, which is larger compared to adhesive wear. Thus, abrasive mode is mainly a severe type of wear.

Abrasive wear can be divided into two groups: two-body and three-body abrasive wear. In the three-body abrasion, the particles formed during the operation or coming from outside the system cause the abrasive wear, whereas in two body, one of the materials plays the role of the abrasive.

Abrasive wear has three different forms: microcuting, wedge forming and ploughing . During operation of a system, transition from one mode to another may happen and modes can act simultaneously. In the ploughing mode, a shallow groove is formed and repeated loading is necessary to form a wear particle. In the wedge forming, the wedge type of wear debris is formed. In the microcutting mode, long, curled ribbon-like particles are generated. The shape of the abrasive particle, the hardness, the load and the shear strength at the contact interface determine the state of the abrasive wear. The abrasive wear coefficients of metals are in the range of depending on the conditions, which is larger compared to adhesive wear. Thus, abrasive mode is mainly a severe type of wear.

Abrasive wear can be divided into two groups: two-body and three-body abrasive wear. In the three-body abrasion, the particles formed during the operation or coming from outside the system cause the abrasive wear, whereas in two body, one of the materials plays the role of the abrasive.

Abrasive wear has three different forms: microcuting, wedge forming and ploughing . During operation of a system, transition from one mode to another may happen and modes can act simultaneously. In the ploughing mode, a shallow groove is formed and repeated loading is necessary to form a wear particle. In the wedge forming, the wedge type of wear debris is formed. In the microcutting mode, long, curled ribbon-like particles are generated. The shape of the abrasive particle, the hardness, the load and the shear strength at the contact interface determine the state of the abrasive wear. The abrasive wear coefficients of metals are in the range of depending on the conditions, which is larger compared to adhesive wear. Thus, abrasive mode is mainly a severe type of wear.