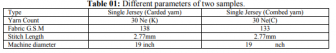

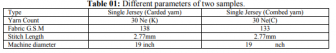

The demand of knit fabric is increasing day by day. Both carded and combed yarns are used to produce knit fabric. A yarn produced from fibers that have been carded but not combed is known as card yarn. On the other hand, the yarn produced from fibers that have been combed is known as combed yarn. In this process, the fibers are arranged in highly parallel form and additional short fibers are removed, producing high quality yarn with excellent strength, fineness and uniformity [1]. In addition, a yarn made of combed cotton fiber needs less twist than carded yarn [2]. There are mainly four basic weft knitted fabrics such as plain fabric or single jersey fabric, rib fabric, interlock fabric and purl fabric [3]. Among these fabrics, single jersey knit fabric is used for this study.

Two major knit fabric properties such as Pilling and Abrasion Resistance were tested to perform this research work. Abrasion resistance and pilling performance are two of the most important mechanical characteristics of fabrics. The resistance of a fabric against the force of friction is known as the abrasion resistance. In general, pilling is a fabric defect observed as small fiber ball or a group consisting of intervened fibers that are attached to the fabric surface by one or more fibers.

Pilling is a surface defect of textiles caused by wear, and is considered unsightly. It happens when washing and wearing of fabrics causes loose fibers to begin to push out from the surface of the cloth, and, over time, abrasion causes the fibers to develop into small spherical bundles, anchored to the surface of the fabric by protruding fibers that haven't broken. The textile industry divides pilling into four stages: fuzz formation, entanglement, growth, and wear-off [5]. Pilling normally happens on the parts of clothing that receive the most abrasion in day-to-day wear, such as the collar, cuffs, and around the thighs and rear on trousers[6]. Pilling can seriously compromise a textile's acceptability for consumers, and is the focus of significant industry research. In the textile industry, severity of pilling is objectively evaluated using five parameters like pill number, the mean area of pilling; the total area of pilling; contrast, and density [7]. Abrasion resistance is a major factor in determining the lifespan of many textile products. It is influenced by all parts of a fabric?s hierarchy: by the fiber, by the yarn structure, and by the webbing construction type. Abrasion is a wear process. Wear is erosion or movement that occurs on a solid surface when it comes into contact with another surface and includes adhesive wear, abrasion, surface fatigue, erosion and fretting wear.

Abrasion resistance? is not described by the Textile Institute, but is defined by ASTM as the resistance to abrasion, usually stated in terms of a number of abrasion cycles. Academics at Leeds University have described abrasion as “the physical destruction of fibers, yarns, and fabrics, resulting from the rubbing of a textile surface over another surface”. Abrasion resistance of the textile materials is very complex phenomenon and affected by many factors, mainly classified as follows: Fiber, yarn, fabric properties and finishing processes. Some of these parameters affect fabric surface whereas some of them has an influence on internal structure of the fabrics. An increase in fabrics abrasion resistance generally increases weft tension.

Literature Review:

Mechanical characteristics are very important within fabric characteristics. The mechanical

characteristics of fabrics generally affect fiber, yarn and fabric characteristics and the finishing process.Pilling rarely effect the actual durability of a fabric but effect adversely in processing as well as to the physical properties of the fabric like appearance, handle etc. [10]. There are many factors, such as the many spinning system, fabric construction and finishing operation, which effect the abrasion resistance and pilling performance. With certain precautions taken in fabric production, the abrasion resistance and pilling performance knit fabrics can be developed positively. Many textile scientists have studied factors that have an effect on pilling and abrasion resistance。

Frictional or abrasive force is one of the most important factors for the pill information. Other factor remaining unchanged increased in frictional or abrasive force increasing pilling [10]. Betran et al. stated that the pilling tendencies of woolen jersey and rib knit fabrics can be predicted by looking at fiber, thread and fabric properties using artificial neural network [15]. The study by Nergis and Candan included the pilling performance and abrasion resistance of plain knitted fabric from chenille yarns. The results showed that yarn properties (component yarn count, pile length) and laundering or dry cleaning do not influence the pilling performance and abrasion resistance of dry relaxed fabrics, whose component yarns tend to decrease.

Omero lu & Ulku can, in his experimental studies, investigated the abrasion resistance and pilling performance of plain weave fabrics made from 100% cotton ring carded, ring combed and OE rotor spun yarns. He found that the abrasion resistance and pilling performance of fabrics made from OE rotor spun yarns had a maximum value. However, he determined that the abrasion resistance and pilling performance of fabrics made from ring carded spun yarns had a minimum value . Adanur et al. investigated the abrasion resistance of 3/1 cotton twill fabrics made with different warp and weft tension. They concluded that an increase in fabrics abrasion resistance generally increases weft tension.

Akaydin studied basic knitted fabrics from ring combed and compact yarns and determined that the abrasion resistance and pilling performance of supreme fabric were lower than interlock fabrics. He ascribed this situation to interlock fabric being more stable, thicker and voluminous than supreme fabric and to the characteristic of knit construction。

Materials & Methods:

3.1 Materials

Sample:

1. Single Jersey (made from carded yarn)

2. Single Jersey (made from combed yarn)

3.2 Methods

The standard temperate atmosphere for conditioning and testing textiles as defined in ISO 139 has been used.

i.e. a temperature (20 ± 2)℃ and a relative humidity (65 ± 2)%. In addition to the test apparatus and auxiliary materials specified in ISO 12947-1, a balance, having an accuracy of 1mg is used.

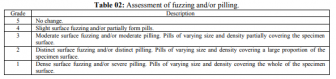

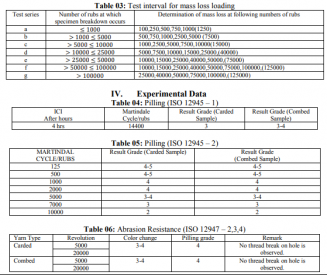

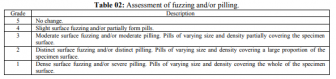

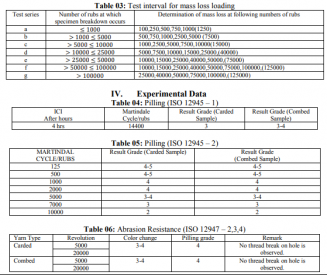

3.2.1 Pilling

Principle: Specimens are mounted on polyurethane tubes and tumbled randomly in a cork-lined box at a constant rotational speed. Fuzzing and pilling is assessed visual after a defined period of tumbling. Any special treatment of the laboratory sample, i.e. washing, cleaning, has to be agreed upon and shall be stated in the test report. Several apparatuses are used in this test like pill testing box, polyurethane specimen tubes, mounting jig,self-adhesive polyvinyl (PVC) tape, sewing machine, viewing cabinet etc.

1.2.2 Abrasion resistance

Principle: A circular specimen is subjected to a defined load and rubbed against an abrasive medium (standard fabric) in a transitional movement tracing a lissome figure. The specimen holder containing the abrasive medium is additionally freely rotatable around its own axis perpendicular to the plane of the specimen. The evaluation of the abrasion resistance of the textile fabric is determined from assessment of the appearance change.

Tests are performed using the mass of the specimen holder and spindle alone at (198 ± 2) g.

The surface change of the test specimen is assessed and compared with an untested specimen of the same fabric,with the option of using methods:

· Abrasion testing to an agreed number of rubs and assessing whether a surface change has occurred.

· Abrasion testing to an agreed surface change and determination of the test interval in which the surface

change has been produced.

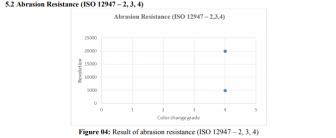

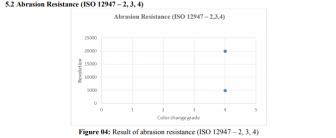

In (ISO 12947 – 2, 3, 4) method, in assessing the abrasion resistance effects we found the same result for both Carded and Combed yarn. After 4 hours 5000, 20000 revolutions, the color change grade for carded and combed yarn is 3 to 4 and pilling grade is 4.

Conclusion:

In this study, the effect of combed and carded yarn on knit fabric properties especially on pilling and abrasion resistance has been analyzed. This experiment will help the textile technologist to take many important decisions in the factory whether we need to use carded yarn or combed yarn. According to study, it can be concluded that in case of abrasion resistance there will be little bit differences between carded and combed yarn but in case of pilling there will be significant differences. So, it is obvious that the outcome of this study will be beneficial for the textile engineers in selecting the suitable yarn to make the fabric with desired properties.

Acknowledgement:

We would like to give special thanks to Mr. Ariful Islam (Former lab officer, Esquire Group) who conducted all of the tests of this study and also grateful to Esquire Group to give the opportunity to use their textile testing and quality control lab.

3.2 Methods

The standard temperate atmosphere for conditioning and testing textiles as defined in ISO 139 has been used.

i.e. a temperature (20 ± 2)℃ and a relative humidity (65 ± 2)%. In addition to the test apparatus and auxiliary materials specified in ISO 12947-1, a balance, having an accuracy of 1mg is used.

3.2.1 Pilling

Principle: Specimens are mounted on polyurethane tubes and tumbled randomly in a cork-lined box at a constant rotational speed. Fuzzing and pilling is assessed visual after a defined period of tumbling. Any special treatment of the laboratory sample, i.e. washing, cleaning, has to be agreed upon and shall be stated in the test report. Several apparatuses are used in this test like pill testing box, polyurethane specimen tubes, mounting jig,self-adhesive polyvinyl (PVC) tape, sewing machine, viewing cabinet etc.

3.2 Methods

The standard temperate atmosphere for conditioning and testing textiles as defined in ISO 139 has been used.

i.e. a temperature (20 ± 2)℃ and a relative humidity (65 ± 2)%. In addition to the test apparatus and auxiliary materials specified in ISO 12947-1, a balance, having an accuracy of 1mg is used.

3.2.1 Pilling

Principle: Specimens are mounted on polyurethane tubes and tumbled randomly in a cork-lined box at a constant rotational speed. Fuzzing and pilling is assessed visual after a defined period of tumbling. Any special treatment of the laboratory sample, i.e. washing, cleaning, has to be agreed upon and shall be stated in the test report. Several apparatuses are used in this test like pill testing box, polyurethane specimen tubes, mounting jig,self-adhesive polyvinyl (PVC) tape, sewing machine, viewing cabinet etc.

1.2.2 Abrasion resistance

Principle: A circular specimen is subjected to a defined load and rubbed against an abrasive medium (standard fabric) in a transitional movement tracing a lissome figure. The specimen holder containing the abrasive medium is additionally freely rotatable around its own axis perpendicular to the plane of the specimen. The evaluation of the abrasion resistance of the textile fabric is determined from assessment of the appearance change.

Tests are performed using the mass of the specimen holder and spindle alone at (198 ± 2) g.

The surface change of the test specimen is assessed and compared with an untested specimen of the same fabric,with the option of using methods:

· Abrasion testing to an agreed number of rubs and assessing whether a surface change has occurred.

· Abrasion testing to an agreed surface change and determination of the test interval in which the surface

change has been produced.

1.2.2 Abrasion resistance

Principle: A circular specimen is subjected to a defined load and rubbed against an abrasive medium (standard fabric) in a transitional movement tracing a lissome figure. The specimen holder containing the abrasive medium is additionally freely rotatable around its own axis perpendicular to the plane of the specimen. The evaluation of the abrasion resistance of the textile fabric is determined from assessment of the appearance change.

Tests are performed using the mass of the specimen holder and spindle alone at (198 ± 2) g.

The surface change of the test specimen is assessed and compared with an untested specimen of the same fabric,with the option of using methods:

· Abrasion testing to an agreed number of rubs and assessing whether a surface change has occurred.

· Abrasion testing to an agreed surface change and determination of the test interval in which the surface

change has been produced.

In (ISO 12947 – 2, 3, 4) method, in assessing the abrasion resistance effects we found the same result for both Carded and Combed yarn. After 4 hours 5000, 20000 revolutions, the color change grade for carded and combed yarn is 3 to 4 and pilling grade is 4.

Conclusion:

In this study, the effect of combed and carded yarn on knit fabric properties especially on pilling and abrasion resistance has been analyzed. This experiment will help the textile technologist to take many important decisions in the factory whether we need to use carded yarn or combed yarn. According to study, it can be concluded that in case of abrasion resistance there will be little bit differences between carded and combed yarn but in case of pilling there will be significant differences. So, it is obvious that the outcome of this study will be beneficial for the textile engineers in selecting the suitable yarn to make the fabric with desired properties.

Acknowledgement:

We would like to give special thanks to Mr. Ariful Islam (Former lab officer, Esquire Group) who conducted all of the tests of this study and also grateful to Esquire Group to give the opportunity to use their textile testing and quality control lab.

In (ISO 12947 – 2, 3, 4) method, in assessing the abrasion resistance effects we found the same result for both Carded and Combed yarn. After 4 hours 5000, 20000 revolutions, the color change grade for carded and combed yarn is 3 to 4 and pilling grade is 4.

Conclusion:

In this study, the effect of combed and carded yarn on knit fabric properties especially on pilling and abrasion resistance has been analyzed. This experiment will help the textile technologist to take many important decisions in the factory whether we need to use carded yarn or combed yarn. According to study, it can be concluded that in case of abrasion resistance there will be little bit differences between carded and combed yarn but in case of pilling there will be significant differences. So, it is obvious that the outcome of this study will be beneficial for the textile engineers in selecting the suitable yarn to make the fabric with desired properties.

Acknowledgement:

We would like to give special thanks to Mr. Ariful Islam (Former lab officer, Esquire Group) who conducted all of the tests of this study and also grateful to Esquire Group to give the opportunity to use their textile testing and quality control lab.