This section presents the standardization of abrasion test or test method for abrasion resistance of concrete surface subjected to the various uses. The test methods that are employed world over to evaluate the abrasion resistance of concrete have attempted with varied success to reproduce the typical forces detrimental to concrete surfaces.

Currently, there are four standard ASTM test methods at International level and one standard Indian Code method for evaluating the resistance of concrete subjected to various types of abrasive actions. ASTM C 418 presents a test method to evaluate the abrasion resistance of concrete by sand blasting technique. ASTM C 944 test method measures the abrasion resistance of concrete by rotating-cutter machine. ASTM C 779 method evaluates the abrasion resistance of horizontal concrete surface by either revolving disc machine or by ball bearing machine and ASTM C 1138 method evaluates the resistance of concrete surfaces subjected to abrasive action of water borne particles on hydraulic structures.

Testing Methods and Procedures

A brief detail of the above mentioned four ASTM methods is presented in the following paragraphs:

1、Test Method for Abrasion Resistance of Concrete by Sand Blasting(ASTM C 418)

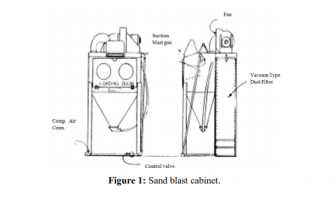

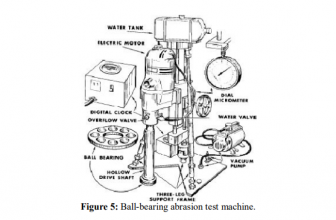

This test method is based on the principle of producing abrasion by sandblasting (Fig.

1). This procedure simulates the action of waterborne particles and abrasives under traffic on concrete surface. Controlling the pressure and the type of abrasive allows the researcher to vary the severity of abrasion. The blast cabinet is equipped with an injector type blast gun with high velocity air jet (Figure 1.). The adjusting parameters are gradation of sand, air pressure, rate of feed of the abrasive charge and distance of the nozzle from the surface.

2、Test Method for Obtaining and Testing Drilled Cores and Sawed Beams of Concrete (ASTM C 944)

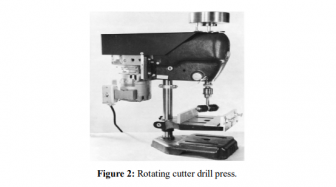

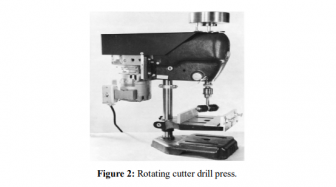

ASTM test method for abrasion resistance of concrete by drilled cores and sawed beams of concrete gives an indication of the relative abrasion resistance of mortar and concrete based on testing of cored or fabricated specimens. The test apparatus consists of rotating cutter and drill press (Figure 2.). The difficulty in maintaining a constant load on the abrading cutter when using the lever, gear and spring system of a drill press has been eliminated by placing a constant load of 98 N directly upon the spindle that turns the cutter.

3、Test Method for Horizontal Concrete Surfaces (ASTM C 779):

There are three types of procedure in the ASTM standard method for abrasion resistance of horizontal concrete surfaces.

1) Revolving-disk machine

2) Dressing wheel machine

3) Ball bearing machine

The above mentioned three machines are portable and adaptable for laboratory and in-place field abrasion testing.

4、Revolving-Disk Machine

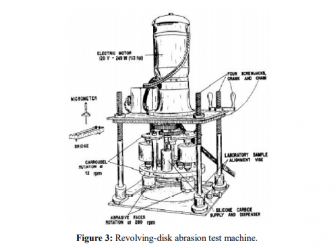

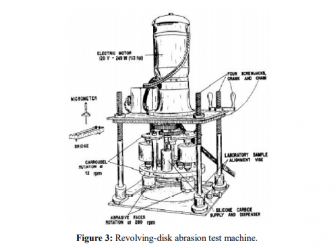

The revolving-disk machine introduces frictional forces by rubbing and grinding

Sliding and scuffing is accomplished by rotating steel disks in conjunction with abrasive grit. Silicon carbide abrasive is used to feed on the disks at the rate of 4-6g/min. A test period of 30 min generally produces significant wear on most concrete surfaces, but it is recommended to extend the test period to 60 min.

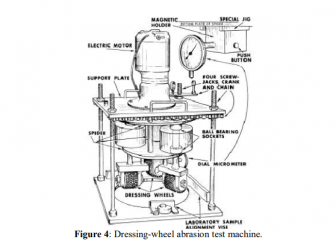

5、Dressing Wheel Machine

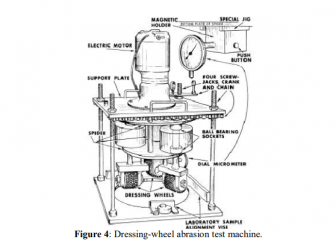

The dressing wheel machine is similar to revolving disk machine, except three sets of seven dressing wheels mounted on horizontal shafts take the place of the three rotating steel disks (Figure.4.). No abrasive materials are employed in the dressing wheel machine. Initial and intermediate measurements of the test path are taken with a depth micrometer. Tracking of dressing wheel normally leaves a grooved path with the test surface being irregular and fairly rough as harder aggregate particles stand out from the softer aggregates particles and mortar that are abraded more quickly. The dressing wheel produces a depth of wear more than double that obtained with the revolving-disk machine for the same test duration. Abrasion of concrete induced by the dressingwheel machine closely simulates the rolling, pounding, and cutting action of steel wheel.

6、Ball Bearing Machine

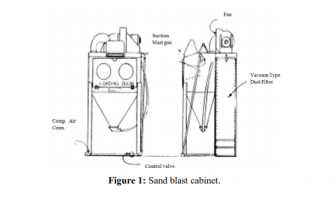

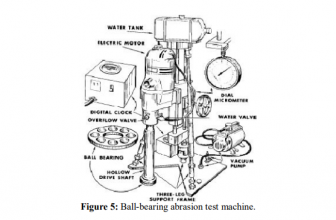

The ball-bearing machine operates on the principle of a series of eight ball bearings rotating under load at a speed of 1000 rpm on wet concrete test surface (Figure 5.).

The water is used to flush out loose particles from the test path, bringing the ball bearing in contact with sand and stone particles still bonded to the concrete surface,thus providing impact as well as sliding friction. Abrasion readings are taken every 50s with a dial micrometer mounted directly to the supporting shaft allowing reading on the fly. Readings are to be measured for a total of 1200 s or until a maximum depth of 3.0 mm is reached. The loss of test accuracy may develop due to rapid wear of steel balls, differences in age levels of concrete, insufficient number of wear readings.

7、Test Method for Abrasion Resistance Of Concrete –Underwater Method(ASTM C 1138)

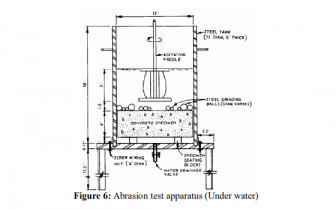

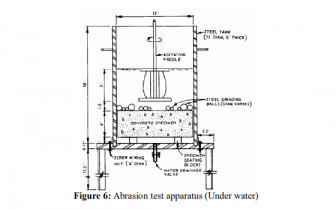

ASTM Test method for abrasion resistance of concrete (Underwater method) was originally developed by Liu in 1980 for evaluating the resistance of concrete surface subjected to abrasion action of water particles on hydraulic structures such as stilling basin, spillways etc. The apparatus consists of essentially a drill press, an agitation paddle, a cylindrical steel container and 70 steel grinding balls of various sizes. Figure 6 shows the cross section view of the test apparatus. The water in the container is circulated by the immersion of agitation paddle that is powered by drill press rotating at a speed of 1200 rpm. The circulating water, in turn, moves the abrasive charges on the surface on the concrete specimen, producing the abrasion effects. The standard test consists of six 12 hours test periods for a total of 72 hours.

Classification of Concrete Abrasion

Classification of Concrete Abrasion

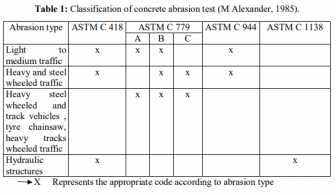

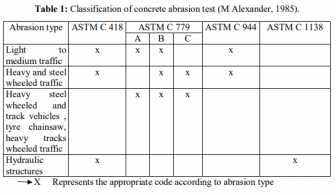

It is clear from the previous section that there is no single test capable of simulating all types of field abrasive action. Table 1 presents the suitability of different code procedures with respect to various abrasion test.

Conclusion

Conclusion

The paper presents a classification and detailed discussion of different tests being currently used to measure abrasion resistance of concrete. From the comparative study,it is clear that ASTM C 799 test procedure is suitable for simulating most of the traffic related abrasive actions, while the abrasion resistance of concrete in hydraulic structures like dams and spillways etc., can be better studies using underwater abrasion test of ASTM C 1138.

2、Test Method for Obtaining and Testing Drilled Cores and Sawed Beams of Concrete (ASTM C 944)

ASTM test method for abrasion resistance of concrete by drilled cores and sawed beams of concrete gives an indication of the relative abrasion resistance of mortar and concrete based on testing of cored or fabricated specimens. The test apparatus consists of rotating cutter and drill press (Figure 2.). The difficulty in maintaining a constant load on the abrading cutter when using the lever, gear and spring system of a drill press has been eliminated by placing a constant load of 98 N directly upon the spindle that turns the cutter.

2、Test Method for Obtaining and Testing Drilled Cores and Sawed Beams of Concrete (ASTM C 944)

ASTM test method for abrasion resistance of concrete by drilled cores and sawed beams of concrete gives an indication of the relative abrasion resistance of mortar and concrete based on testing of cored or fabricated specimens. The test apparatus consists of rotating cutter and drill press (Figure 2.). The difficulty in maintaining a constant load on the abrading cutter when using the lever, gear and spring system of a drill press has been eliminated by placing a constant load of 98 N directly upon the spindle that turns the cutter.

3、Test Method for Horizontal Concrete Surfaces (ASTM C 779):

There are three types of procedure in the ASTM standard method for abrasion resistance of horizontal concrete surfaces.

1) Revolving-disk machine

2) Dressing wheel machine

3) Ball bearing machine

The above mentioned three machines are portable and adaptable for laboratory and in-place field abrasion testing.

4、Revolving-Disk Machine

The revolving-disk machine introduces frictional forces by rubbing and grinding

3、Test Method for Horizontal Concrete Surfaces (ASTM C 779):

There are three types of procedure in the ASTM standard method for abrasion resistance of horizontal concrete surfaces.

1) Revolving-disk machine

2) Dressing wheel machine

3) Ball bearing machine

The above mentioned three machines are portable and adaptable for laboratory and in-place field abrasion testing.

4、Revolving-Disk Machine

The revolving-disk machine introduces frictional forces by rubbing and grinding

Sliding and scuffing is accomplished by rotating steel disks in conjunction with abrasive grit. Silicon carbide abrasive is used to feed on the disks at the rate of 4-6g/min. A test period of 30 min generally produces significant wear on most concrete surfaces, but it is recommended to extend the test period to 60 min.

5、Dressing Wheel Machine

The dressing wheel machine is similar to revolving disk machine, except three sets of seven dressing wheels mounted on horizontal shafts take the place of the three rotating steel disks (Figure.4.). No abrasive materials are employed in the dressing wheel machine. Initial and intermediate measurements of the test path are taken with a depth micrometer. Tracking of dressing wheel normally leaves a grooved path with the test surface being irregular and fairly rough as harder aggregate particles stand out from the softer aggregates particles and mortar that are abraded more quickly. The dressing wheel produces a depth of wear more than double that obtained with the revolving-disk machine for the same test duration. Abrasion of concrete induced by the dressingwheel machine closely simulates the rolling, pounding, and cutting action of steel wheel.

Sliding and scuffing is accomplished by rotating steel disks in conjunction with abrasive grit. Silicon carbide abrasive is used to feed on the disks at the rate of 4-6g/min. A test period of 30 min generally produces significant wear on most concrete surfaces, but it is recommended to extend the test period to 60 min.

5、Dressing Wheel Machine

The dressing wheel machine is similar to revolving disk machine, except three sets of seven dressing wheels mounted on horizontal shafts take the place of the three rotating steel disks (Figure.4.). No abrasive materials are employed in the dressing wheel machine. Initial and intermediate measurements of the test path are taken with a depth micrometer. Tracking of dressing wheel normally leaves a grooved path with the test surface being irregular and fairly rough as harder aggregate particles stand out from the softer aggregates particles and mortar that are abraded more quickly. The dressing wheel produces a depth of wear more than double that obtained with the revolving-disk machine for the same test duration. Abrasion of concrete induced by the dressingwheel machine closely simulates the rolling, pounding, and cutting action of steel wheel.

6、Ball Bearing Machine

The ball-bearing machine operates on the principle of a series of eight ball bearings rotating under load at a speed of 1000 rpm on wet concrete test surface (Figure 5.).

6、Ball Bearing Machine

The ball-bearing machine operates on the principle of a series of eight ball bearings rotating under load at a speed of 1000 rpm on wet concrete test surface (Figure 5.).

The water is used to flush out loose particles from the test path, bringing the ball bearing in contact with sand and stone particles still bonded to the concrete surface,thus providing impact as well as sliding friction. Abrasion readings are taken every 50s with a dial micrometer mounted directly to the supporting shaft allowing reading on the fly. Readings are to be measured for a total of 1200 s or until a maximum depth of 3.0 mm is reached. The loss of test accuracy may develop due to rapid wear of steel balls, differences in age levels of concrete, insufficient number of wear readings.

7、Test Method for Abrasion Resistance Of Concrete –Underwater Method(ASTM C 1138)

ASTM Test method for abrasion resistance of concrete (Underwater method) was originally developed by Liu in 1980 for evaluating the resistance of concrete surface subjected to abrasion action of water particles on hydraulic structures such as stilling basin, spillways etc. The apparatus consists of essentially a drill press, an agitation paddle, a cylindrical steel container and 70 steel grinding balls of various sizes. Figure 6 shows the cross section view of the test apparatus. The water in the container is circulated by the immersion of agitation paddle that is powered by drill press rotating at a speed of 1200 rpm. The circulating water, in turn, moves the abrasive charges on the surface on the concrete specimen, producing the abrasion effects. The standard test consists of six 12 hours test periods for a total of 72 hours.

The water is used to flush out loose particles from the test path, bringing the ball bearing in contact with sand and stone particles still bonded to the concrete surface,thus providing impact as well as sliding friction. Abrasion readings are taken every 50s with a dial micrometer mounted directly to the supporting shaft allowing reading on the fly. Readings are to be measured for a total of 1200 s or until a maximum depth of 3.0 mm is reached. The loss of test accuracy may develop due to rapid wear of steel balls, differences in age levels of concrete, insufficient number of wear readings.

7、Test Method for Abrasion Resistance Of Concrete –Underwater Method(ASTM C 1138)

ASTM Test method for abrasion resistance of concrete (Underwater method) was originally developed by Liu in 1980 for evaluating the resistance of concrete surface subjected to abrasion action of water particles on hydraulic structures such as stilling basin, spillways etc. The apparatus consists of essentially a drill press, an agitation paddle, a cylindrical steel container and 70 steel grinding balls of various sizes. Figure 6 shows the cross section view of the test apparatus. The water in the container is circulated by the immersion of agitation paddle that is powered by drill press rotating at a speed of 1200 rpm. The circulating water, in turn, moves the abrasive charges on the surface on the concrete specimen, producing the abrasion effects. The standard test consists of six 12 hours test periods for a total of 72 hours.

Classification of Concrete Abrasion

It is clear from the previous section that there is no single test capable of simulating all types of field abrasive action. Table 1 presents the suitability of different code procedures with respect to various abrasion test.

Classification of Concrete Abrasion

It is clear from the previous section that there is no single test capable of simulating all types of field abrasive action. Table 1 presents the suitability of different code procedures with respect to various abrasion test.

Conclusion

The paper presents a classification and detailed discussion of different tests being currently used to measure abrasion resistance of concrete. From the comparative study,it is clear that ASTM C 799 test procedure is suitable for simulating most of the traffic related abrasive actions, while the abrasion resistance of concrete in hydraulic structures like dams and spillways etc., can be better studies using underwater abrasion test of ASTM C 1138.

Conclusion

The paper presents a classification and detailed discussion of different tests being currently used to measure abrasion resistance of concrete. From the comparative study,it is clear that ASTM C 799 test procedure is suitable for simulating most of the traffic related abrasive actions, while the abrasion resistance of concrete in hydraulic structures like dams and spillways etc., can be better studies using underwater abrasion test of ASTM C 1138.