Abrasion resistance is measured in a laboratory by rotating a paper sample under abrasive wheels for a set length of time, and then measuring the sample's change in weight. Wet or dry abrasion resistance tests can be performed.

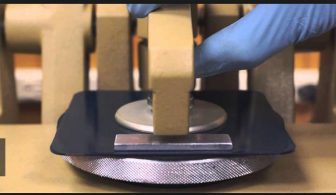

[caption id="attachment_1423" align="aligncenter" width="336"]

Abrasion test[/caption]

The measurement of abrasion resistance, usually by the weighing of a material sample before and after subjecting it to a known abrasive stress throughout a known time period, or by reflectance or surface finish comparisons, or by dimensional comparisons.

Abrasion testing is of interest in a number of technical fields, including civil and mechanical engineering,reliability engineering, metallurgy, and geology. These tests are of importance in ensuring the durability of a material in a particular product or application,and in ensuring that material that erodes because of abrasion does not cause environmental or safety hazards in the production or test environments or in use of the product.

Several factors are typically considered in developing or selecting an appropriate abrasion test for the application at hand.The shape of the contact area is taken into consideration, as is the composition of the two surfaces making contact with one another. Speed of sliding contact between the two surfaces, the force with which they act on one another,and the duration of contact between them may also be considered. In addition to the materials themselves, the environment in which they are making contact also plays a role in selecting an appropriate abrasion test.

Factors affecting abrasion resistance:

1)Fibre type:Nylon is generally considered to have the best abrasion resistance. Polyester and polypropylene also have good abrasion resistance. Blending either nylon or polyester with wool and cotton is found to increase their abrasion resistance. Viscose and acetates have the lowest abrasion resistance.

2)Fibre properties:A fabric made up with longer fibres gives better abrasion resistance than short fibres because they are harder to remove from the yarn. For the same reason filament yarns are more abrasion resistant than staple yarns made from the same fibre. Increasing fibre diameter up to a limit improves abrasion resistance.

3)Yarn twist:An optimum amount of twist in a yarn gives the best abrasion resistance. At low-twist factors, fibres can easily be removed from the yarn so that it is gradually reduced in diameter. At high twist levels, the fibres are held more tightly but the yarn is stiffer so it is hard abrade under pressure

4)Fabric structure:Fabrics with the crimp evenly distributed between warp and weft give the best wear because the damage is spread evenly between them.

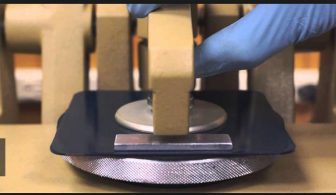

Abrasion test[/caption]

The measurement of abrasion resistance, usually by the weighing of a material sample before and after subjecting it to a known abrasive stress throughout a known time period, or by reflectance or surface finish comparisons, or by dimensional comparisons.

Abrasion testing is of interest in a number of technical fields, including civil and mechanical engineering,reliability engineering, metallurgy, and geology. These tests are of importance in ensuring the durability of a material in a particular product or application,and in ensuring that material that erodes because of abrasion does not cause environmental or safety hazards in the production or test environments or in use of the product.

Several factors are typically considered in developing or selecting an appropriate abrasion test for the application at hand.The shape of the contact area is taken into consideration, as is the composition of the two surfaces making contact with one another. Speed of sliding contact between the two surfaces, the force with which they act on one another,and the duration of contact between them may also be considered. In addition to the materials themselves, the environment in which they are making contact also plays a role in selecting an appropriate abrasion test.

Factors affecting abrasion resistance:

1)Fibre type:Nylon is generally considered to have the best abrasion resistance. Polyester and polypropylene also have good abrasion resistance. Blending either nylon or polyester with wool and cotton is found to increase their abrasion resistance. Viscose and acetates have the lowest abrasion resistance.

2)Fibre properties:A fabric made up with longer fibres gives better abrasion resistance than short fibres because they are harder to remove from the yarn. For the same reason filament yarns are more abrasion resistant than staple yarns made from the same fibre. Increasing fibre diameter up to a limit improves abrasion resistance.

3)Yarn twist:An optimum amount of twist in a yarn gives the best abrasion resistance. At low-twist factors, fibres can easily be removed from the yarn so that it is gradually reduced in diameter. At high twist levels, the fibres are held more tightly but the yarn is stiffer so it is hard abrade under pressure

4)Fabric structure:Fabrics with the crimp evenly distributed between warp and weft give the best wear because the damage is spread evenly between them.

Abrasion test[/caption]

The measurement of abrasion resistance, usually by the weighing of a material sample before and after subjecting it to a known abrasive stress throughout a known time period, or by reflectance or surface finish comparisons, or by dimensional comparisons.

Abrasion testing is of interest in a number of technical fields, including civil and mechanical engineering,reliability engineering, metallurgy, and geology. These tests are of importance in ensuring the durability of a material in a particular product or application,and in ensuring that material that erodes because of abrasion does not cause environmental or safety hazards in the production or test environments or in use of the product.

Several factors are typically considered in developing or selecting an appropriate abrasion test for the application at hand.The shape of the contact area is taken into consideration, as is the composition of the two surfaces making contact with one another. Speed of sliding contact between the two surfaces, the force with which they act on one another,and the duration of contact between them may also be considered. In addition to the materials themselves, the environment in which they are making contact also plays a role in selecting an appropriate abrasion test.

Factors affecting abrasion resistance:

1)Fibre type:Nylon is generally considered to have the best abrasion resistance. Polyester and polypropylene also have good abrasion resistance. Blending either nylon or polyester with wool and cotton is found to increase their abrasion resistance. Viscose and acetates have the lowest abrasion resistance.

2)Fibre properties:A fabric made up with longer fibres gives better abrasion resistance than short fibres because they are harder to remove from the yarn. For the same reason filament yarns are more abrasion resistant than staple yarns made from the same fibre. Increasing fibre diameter up to a limit improves abrasion resistance.

3)Yarn twist:An optimum amount of twist in a yarn gives the best abrasion resistance. At low-twist factors, fibres can easily be removed from the yarn so that it is gradually reduced in diameter. At high twist levels, the fibres are held more tightly but the yarn is stiffer so it is hard abrade under pressure

4)Fabric structure:Fabrics with the crimp evenly distributed between warp and weft give the best wear because the damage is spread evenly between them.