Although fabric softeners have been in use since the 1930s, their demand increased greatly in the 1950s due to several factors including the introduction of synthetic fibers, detergents, and the advent of the modern washing machine and automatic dryer. Abrasion from mechanical agitation of automatic washers caused surface fuzz formation in fabrics, as well as distortion and entanglement of fibers,more rapidly than earlier wringer washing machines had. The entangled fibers were further set by the automatic dryers; this produced a stiff and harsh hand which prompted interest in and a market for home laundry softeners.4 In addition, synthetic detergents removed the oils and waxes that served as lubricants in natural fibers. Synthetic detergents, therefore,resulted in very clean but harsh, scratchy,and uncomfortable fabrics to wear.5 Fabric softeners were needed to counteract these effects. Another factor contributing to the increased use of fabric softeners is that synthetic fibers are prone to static build up which can be objectionable to the wearer. Fabric softeners act as antistatic agents by enabling synthetic fibers to retain sufficient moisture to dissipate static charges.6 Household softeners, both liquid and dryer sheet, work by coating yarn and fibers with lubricants and humectants.7 The lubricants make fabrics feel smooth, soft, and flexible by internal lubrication of the fibers. Humectants help fibers to retain moisture, a factor that is crucial in antistatic treatment.

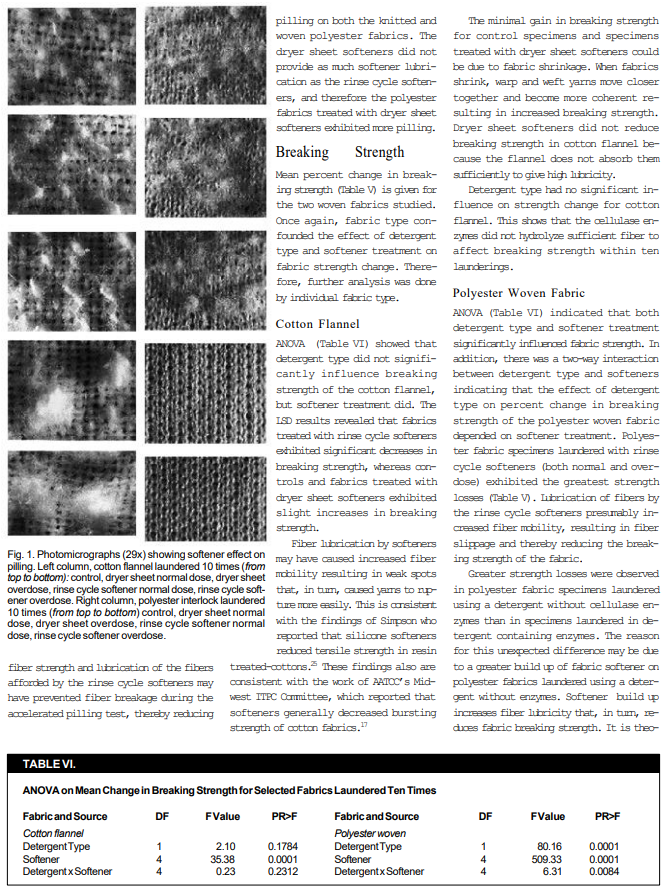

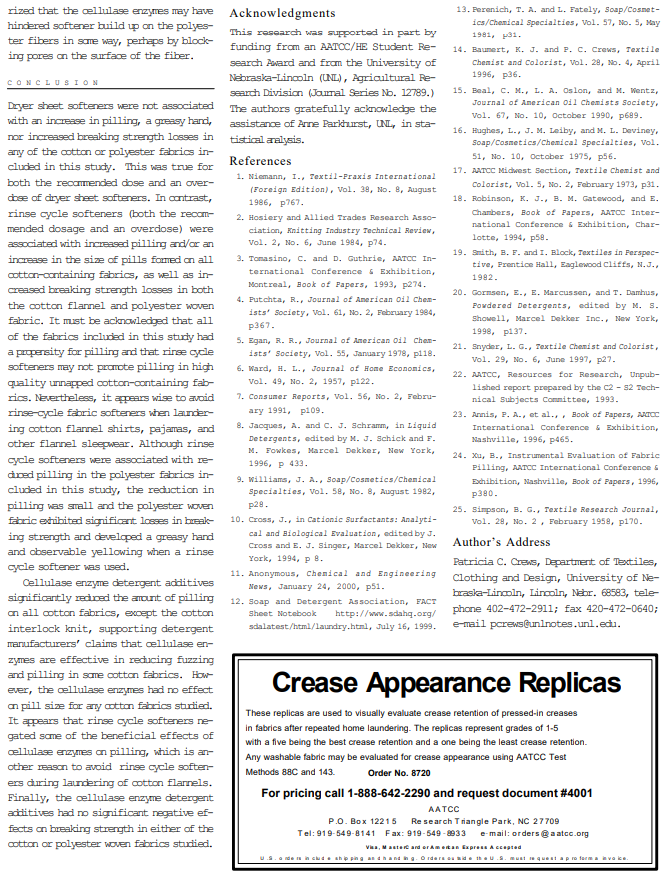

Until recently, household fabric softeners were formulated from three main chemical classes of cationic surfactants: dialkyldimethyl ammonium compounds,imidazolinium compounds, and diamido alkoxylated ammonium compounds.8-10 In the 1990s, esters of dimethyl ammonium compounds (so-called ester quats) supplanted all other softener types in Europe due to concerns about the biodegradability of dialkyl quaternary compounds. Only one major U.S. company has switched to ester quats, and did so quietly and without environmental claims around 1996.11 Dryer sheet softeners“contain essentially the same type of cationic compounds as washer-added liquids, with minor differences to ensure compatibility with the clothes dryer.”12 Dryer sheet softeners impart less lubrication, and therefore less softening, to fabrics than rinse cycle softeners.9 On the other hand, dryer sheet softeners control static cling better than rinse cycle softeners.9 Although a number of studies have been published regarding the influence of fabric softeners on textile properties, most of the studies focused on the influence of softeners on fabric hand, absorbency,static properties, abrasion, whiteness,wrinkle recovery, flame retardancy, durable press, and soil release. These did not include fabric pilling.