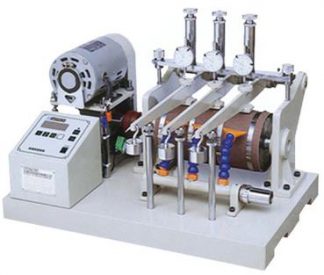

Akron abrasion

Akron abrasion according to GB / T1689-1998 standard, cut the length of 23.5mm, width 12.7mm of the sample fixed to the rubber machine, (23 ± 2) ℃ regulation 3h. The sample clockwise rotation, pre-grinding 20min removed, brush off the dumpling weighing m1. Using the pre-grinding test after the test, driving 1.61km after weighing m2. Ρ is the density of the sample. Akron abrasion V = (m1-m2) / ρ.

Akron abrasion

Akron abrasion according to GB / T1689-1998 standard, cut the length of 23.5mm, width 12.7mm of the sample fixed to the rubber machine, (23 ± 2) ℃ regulation 3h. The sample clockwise rotation, pre-grinding 20min removed, brush off the dumpling weighing m1. Using the pre-grinding test after the test, driving 1.61km after weighing m2. Ρ is the density of the sample. Akron abrasion V = (m1-m2) / ρ.

DIN abrasion

DIN abrasion according to GB / T9867-2008 standard, with a rotary cutter cut diameter (16 ± 0.2) mm, the height of (6 ~ 10) mm cylindrical sample, will be called good quality m1 into the sample In the holder, slide the holder with the sample into the starting point of the roller and place it on a cloth with a specific type. The machine is tested and the experiment is finished when the abrasion stroke reaches 40 m. Remove the sample from the holder and brush the dander and weigh the sample mass. DIN abrasion volume V = (m1-m2) / ρ.

DIN abrasion

DIN abrasion according to GB / T9867-2008 standard, with a rotary cutter cut diameter (16 ± 0.2) mm, the height of (6 ~ 10) mm cylindrical sample, will be called good quality m1 into the sample In the holder, slide the holder with the sample into the starting point of the roller and place it on a cloth with a specific type. The machine is tested and the experiment is finished when the abrasion stroke reaches 40 m. Remove the sample from the holder and brush the dander and weigh the sample mass. DIN abrasion volume V = (m1-m2) / ρ.

Taber abrasion

Taber abrasion was tested according to ASTM D3884-2009 method. A round sample with a diameter of 100 mm and a central aperture of 6.5 mm was cut using a slicer with a sample thickness of 3 mm. Placed in the Taber abrasion test machine fixed clamping the appropriate type of abrasion grinding wheel and to the provisions of the load, set the sample rotation speed of 60r / min, the sample is driven to wear abrasive grinding wheel to wear samples, record the end of the sample number of revolutions The Record the weight of the sample before the test m1 (mg), test the quality of the recorded sample m2 (mg), Taber abrasion value is m1-m2.

Taber abrasion

Taber abrasion was tested according to ASTM D3884-2009 method. A round sample with a diameter of 100 mm and a central aperture of 6.5 mm was cut using a slicer with a sample thickness of 3 mm. Placed in the Taber abrasion test machine fixed clamping the appropriate type of abrasion grinding wheel and to the provisions of the load, set the sample rotation speed of 60r / min, the sample is driven to wear abrasive grinding wheel to wear samples, record the end of the sample number of revolutions The Record the weight of the sample before the test m1 (mg), test the quality of the recorded sample m2 (mg), Taber abrasion value is m1-m2.

NBS abrasion

NBS abrasion according to ASTMD1630-2006 test, with 25mm square cut knife cut the thickness of 6mm sample. Take the standard rubber test piece of Shao A65, fixed with double-sided adhesive in the NBS abrasion arm on the test piece seat, put the arm, the standard rubber test piece contact NBS wear machine drum on the 40 # special abrasive paper. Press the "Test" button to start the pre-grinding until the standard rubber test piece abrasion the curvature and sandpaper bending to stop the pre-grinding. Adjust the striker and record the thickness of the test thickness gauge displayed on the dashboard. The test of the NBS abrasion machine zero, press the "test" until the wear thickness of 2.5mm, record the number of revolutions R1; remove the standard rubber test pieces put on the test sample, repeat the test steps, record the test speed R; The test piece was replaced with a standard rubber test piece before recording the number of revolutions R2. NBS abrasion index is 2R / (R1 + R2) × 100.

NBS abrasion

NBS abrasion according to ASTMD1630-2006 test, with 25mm square cut knife cut the thickness of 6mm sample. Take the standard rubber test piece of Shao A65, fixed with double-sided adhesive in the NBS abrasion arm on the test piece seat, put the arm, the standard rubber test piece contact NBS wear machine drum on the 40 # special abrasive paper. Press the "Test" button to start the pre-grinding until the standard rubber test piece abrasion the curvature and sandpaper bending to stop the pre-grinding. Adjust the striker and record the thickness of the test thickness gauge displayed on the dashboard. The test of the NBS abrasion machine zero, press the "test" until the wear thickness of 2.5mm, record the number of revolutions R1; remove the standard rubber test pieces put on the test sample, repeat the test steps, record the test speed R; The test piece was replaced with a standard rubber test piece before recording the number of revolutions R2. NBS abrasion index is 2R / (R1 + R2) × 100.